Negative Side Waterproofing of Subway Tunnel, South Ferry Station

| Project: | South Ferry Subway Station Tunnel, New York, New York |

| Designer: | Parsons Brinkerhoff |

| Owner: | New York City Transit Authority (Metropolitan Transportation Authority) |

| Contractor: | Sovereign Thyssen |

| Products: | Cem-Kote CW Plus, Cem-Kote Flex ST, Reinforcing Fabric HD |

| Objective: |

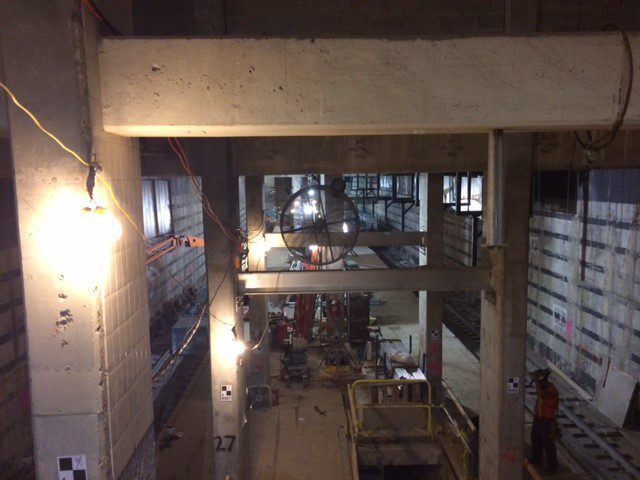

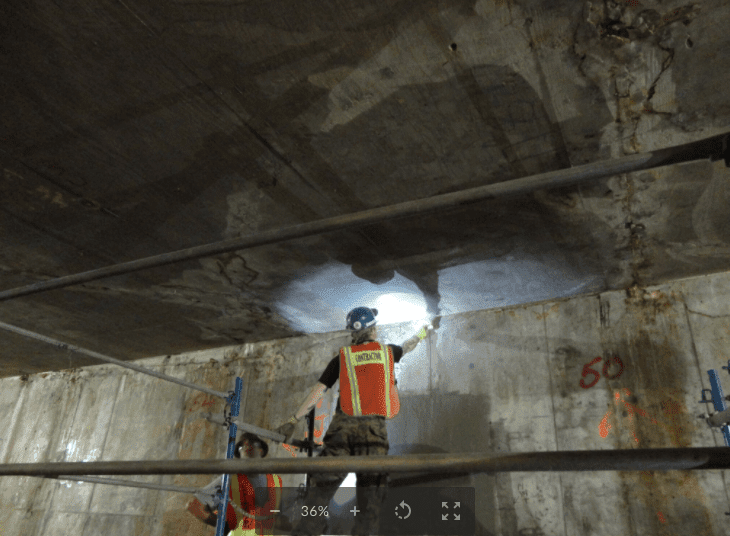

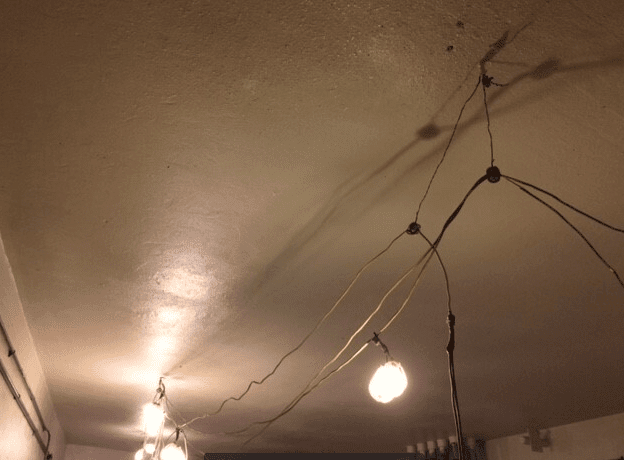

Negative side waterproofing of the subway tunnel, including repair of cracks, construction joints and concrete – Figure 1 show station under repair Deteriorated concrete was repaired with Meadow-Crete GPS, shrinkage compensated, repair mortar. The major problems were an extensive cracking and concrete walls coated with paint and tile adhesive residues – shown in Figure 2. The cracks were treated using flexible Cem-Kote Flex ST, a polymer cement coating, reinforced with Reinforcing Fabric HD. The process of repairing repair of cracks is shown in Figure 3. The surface of the concrete was completely cleaned by grinding and water saturated to achieve surface damp condition. Cem-Kote CW Plus, crystalline waterproofing was spray applied in two coats and allow to wet cure for 3 days. The application of Cem-Kote CW Plus is shown in Figure 4. Completed application of Cem-Kote CW Plus is shown in Figure 7. Some areas, such as separate vaults next to the tunnel, were also painted after Cem-Kote CW Plus was fully cured. Figures 5 & 6 show the underground vault after application of Cem-Kote CW Plus, and also after painting. The high relative humidity and temperature variations resulted occasionally in water condensation appearing on the surface of concrete, as shown in Figure 8. |

Figure 1 South Ferry Station Under Repair.

Figure 2 Typical Concrete Cracking

Figure 3 Concrete Cracking Repair

Figure 4 Cem-Kote CW Plus Spray Application

Figure 5 Vault after Cem-Kote CW Plus Application

Figure 6 Vault with painted Cem-Kote CW Plus

Figure 7 Cem-Kote CW Plus Applied

Figure 8 High Relative Humidity Temperature Variations Note Water Condensing on Concrete Surface