Waterproofing of Drinking Water Concrete Tanks, Brantford, Ontario, Canada

| Project: | Waterproofing of Holmedale WTP Tanks, Brantford, ON |

| Designer: | Proctor Redfern |

| Owner: | City of Brantford |

| Contractor: | Algoma Contractors Ltd., |

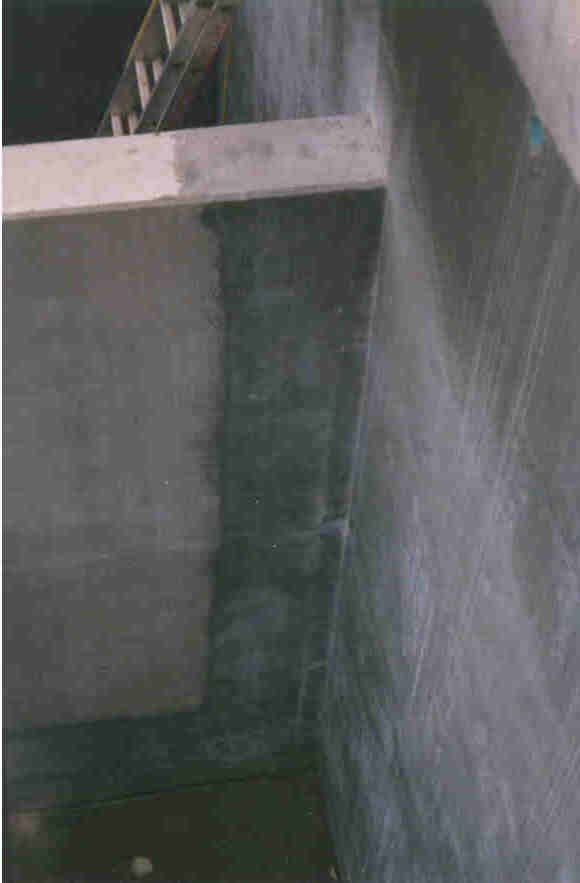

| Products: | Cem-Kote Flex ST |

| Objective: | Water pre-treatment tanks & other tanks of the plant were originally waterproofed using Cem-Kote Flex ST in 1998. The water pre-treatment is in three stages -Tanks #1 & #2 use polymer coagulant and carbon together with circulating sand to remove solid contaminants (river mud). The sand with deposited mud settles to the bottom of the tanks and is pumped out, cleaned and recycled. The sand pumping and cleaning equipment is shown in Figure 1. Figure 2 shows the application of Cem-Kote Flex ST in tank #2 in 1998. Note that the exterior wall is completely coated, and the tank partition wall is coated only to a few feet out.In Tank #3 the residual sludge is allowed to settle and is scraped from the bottom of the tank. The bottom of the tank with scraper as constructed in 1998, is shown in Figure 4 with the Cem-Kote Flex ST in this tank being shown in Figure 5. In spite of the scraping action at the bottom, the Cem-Kote Flex ST remained undamaged During upgrades in 2010, the chorine tanks in this facility were refurbished, and the process changed to ozone treatment. The refurbished ozone treatment tanks are shown in Figures 6 & 7. During upgrades, the surfaces of concrete and Cem-Kote Flex ST were cleaned using 35 MPa (5,000 psi) pressure water -but areas where Cem-Kote Flex ST had to be removed required a water pressure exceeding 82 MPa (12,000 psi). Holmedale water pre-treatment tanks were inspected in October 2011 by representatives of Dillon, Bennett, Algoma and Gemite. Figure 3 shows the same area (as Figure # 2), but after cleaning in October 2011. On the left side of Figure 3 is the dark, uncleaned area of carbonated sludge on the surface of the concrete, in the centre is a strip of clean concrete,and further to the right the surface of Cem-Kote Flex ST is marked by the stream of high pressure water. The performance of Cem-Kote Flex ST protective waterproofing was reviewed with the operator in 2015 and no problems were reported. |

The Top of Tanks Showing Sand Cleaning and Recycling Equipment

Cem-Kote Flex ST Waterproofing Applied to Exterior Wall of the Tank 2_and partly onto the Partion Buffle Buffle wall separating the tanks

Black Area on the left is Concrete Covered with Carbonated Sludge

Tanks #3

Bottom of Tank #3

Chlorine Treatment Tanks Refurbished to Ozone Treatment

Chlorine Treatment Tanks